10 Best Circular Saw Blades 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

Diablo D0724A 7-1/4" 24T Diablo™ Circular Saw Framing Blade

The Diablo D0724A 7-1/4" 24T Circular Saw Framing Blade is a dependable choice for those working with engineered wood. One of its main strengths is its construction material; the blade is made from carbide, which is known for its durability and ability to maintain sharpness over time. The kerf width of 0.059 inches allows for precise cuts with minimal material wastage.

With a blade diameter of 7-1/4 inches and 24 teeth, it is well-suited for framing tasks, providing a good balance between speed and smoothness of cuts. The blade’s tooth configuration supports efficient cutting through engineered wood, making it a suitable option for general carpentry and construction projects. Additionally, the blade’s relatively light weight (0.45 pounds) makes it easy to handle, reducing user fatigue during prolonged use.

However, with only 24 teeth, the blade might not be the best choice for tasks requiring extremely fine or clean cuts such as finish work. Users looking for versatility across a wider range of materials may need to look for other blades as this one is optimized primarily for engineered wood. The Diablo D0724A excels in durability and efficient cutting for framing tasks in engineered wood, making it a practical choice for carpenters and builders who prioritize robust performance in specific woodworking tasks.

Freud LU84R011: 10" Combination Blade

The Freud LU84R011 10-Inch Combination Blade is designed for versatility and high performance in various woodworking tasks. With a 10-inch diameter and 50 teeth, this blade is well-suited for both ripping and crosscutting applications. The combination tooth configuration, including large gullets in front of flat top rakers, aids in fast ripping and chip removal, making it efficient for different cutting needs.

The 0.126-inch kerf width and 0.087-inch plate thickness ensure precise and clean cuts with minimal material waste. Made from a premium TiCo HI-Density Carbide blend, the blade promises durability and long-lasting sharpness, ideal for frequent use on engineered wood and similar materials. The laser-cut anti-vibration slots are a notable feature, significantly reducing vibration and sideways movement, which not only extends the blade's life but also provides a smooth, splinter-free finish.

Additionally, the Perma-Shield Non-Stick Coating minimizes blade drag and protects against corrosion and pitch build-up, enhancing performance and maintenance. The blade's strengths in versatility and finish quality come at a slightly higher price point compared to standard blades. Moreover, the large number of teeth, while providing a fine finish, may not be ideal for users primarily focused on very rough, fast cuts. This blade is an excellent choice for woodworkers seeking a balanced tool for both ripping and crosscutting, prioritizing precision, and finish quality.

Customer Highlights

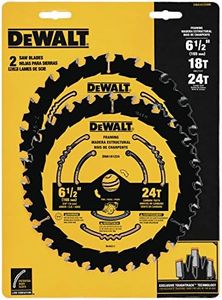

A summary of real customer reviews to highlight what shoppers are saying!10 Pack Freud D0624A Diablo 6-1/2" x 24-Tooth Framing Circular Saw Blade with 5/8" Arbor (Bulk Single Blade)

The 10 Pack Freud D0624A Diablo 6-1/2" x 24-Tooth Framing Circular Saw Blades are designed for ripping and crosscutting wood. With a 6-1/2 inch diameter and 24 teeth, these blades are suitable for framing tasks. The carbide material promises durability, and the red coating enhances visibility and reduces friction.

One of the main strengths of these blades is the laser-cut stabilizer vents which minimize vibration and heat build-up, leading to more precise cuts and a longer lifespan for the blades. The thin kerf design is particularly advantageous for portable and low-powered saws, making these blades versatile for on-site jobs. Additionally, the 5/8" arbor ensures compatibility with a range of saws, and the 3.6-pound weight contributes to ease of handling.

On the downside, international buyers should be aware that terms and conditions might differ from local purchases, potentially affecting warranty and support. Additionally, with a limited number of 24 teeth, these blades might not be as efficient for fine, detailed cuts compared to blades with a higher tooth count. This product is ideal for professionals and DIY enthusiasts looking for robust, long-lasting blades for general framing and woodcutting tasks.