10 Best Solder For Electronics 2025 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

MAIYUM 63-37 Tin Lead Rosin Core Solder Wire for Electrical Soldering (0.8mm 50g)

The MAIYUM 63-37 Tin Lead Rosin Core Solder Wire is a solid choice for anyone engaged in electronics soldering, particularly for DIY projects, circuit boards, and repair work on various electrical devices. With a diameter of 0.8 mm, it is appropriately sized for intricate soldering tasks and the 50g weight makes it convenient for casual use or transportation. The low melting point of 361 °F (183 °C) allows for quick soldering, making it easier to work with while ensuring strong solder joints due to its reliable flow and adherence. The 1.8% flux content helps enhance the solder's performance by minimizing oxidation and improving the bond on surfaces being soldered.

While it’s great for various applications, users who need to solder in high-temperature environments or with specialized materials may find this solder less effective compared to higher-grade or lead-free alternatives.

The MAIYUM solder wire will serve well for general electronics work and hobbyist projects.

Customer Highlights

A summary of real customer reviews to highlight what shoppers are saying!YIHUA 939D+ Digital Soldering Station, 75W Equivalent with Precision Heat Control (392°F to 896°F) and Built-in Transformer. ESD Safe, Lead Free with °C/°F display (Black)

The YIHUA 939D+ Digital Soldering Station is designed for users who engage in regular soldering, making it suitable for both hobbyists and professionals. Its impressive power of 75W and precise temperature control ranging from 392°F to 896°F ensure that you can handle various soldering tasks effectively. The quick heating feature and temperature stabilization technology are great advantages, allowing you to work on projects without long waits and with consistent results.

The station is built with a durable metallic design that can withstand regular use, and it features an ESD-safe design, which is essential for working with sensitive electronic components. The user-friendly digital display showing both Fahrenheit and Celsius, along with intuitive temperature adjustment, makes it accessible for beginners and experienced users alike.

The YIHUA 939D+ is geared towards users who need a robust solution. Casual users or those who only solder occasionally might find it to be more than what they need, leading to unnecessary complexity. Additionally, it's important to note that this soldering station operates on a US-standard voltage, which might limit its use in other countries without appropriate adapters.

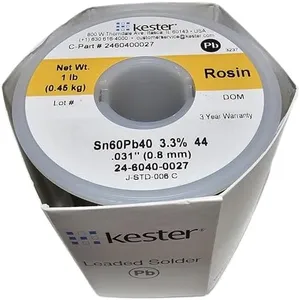

KESTER SOLDER 24-6040-0027 Wire Solder, 0.031"Dia., Pack of (1),32117

The KESTER SOLDER 24-6040-0027 is a well-regarded option for those in the electronics field. Its composition of 60% tin and 40% lead ensures a reliable melting point and strong joints, which is vital for both hobbyists and professionals. The 0.031-inch diameter is suitable for precision work, making it ideal for detailed electronic soldering tasks.

The inclusion of a rosin core with 44 flux (3.3%) aids in smooth solder flow and reduces the need for additional flux, simplifying the process. Being an authentic Kester product manufactured in the USA adds to its credibility and reliability. However, its halogen content might be a concern for those looking for halogen-free options due to environmental or health reasons.

Additionally, while the product is durable and strong, the presence of lead means it should be handled with care, particularly in environments where lead exposure is a concern. This product is best suited for experienced electronics enthusiasts or professionals who require a dependable and precise soldering wire.